Can You Use Electrical Tape Instead of Caps for Electrical Connections?

In the world of electrical connections, traditional caps like wing nuts or twist-on connectors have long been the standard for ensuring secure and safe circuits. But have you ever wondered if there's an alternative? In this blog, we'll explore the possibility of using electrical tape in place of these caps.

While caps have their advantages, electrical tape can serve as a temporary solution in certain situations. Let's delve into the pros and cons and determine when it's acceptable to use electrical tape for electrical connections.

What Is Electrical Tape?

Open up any old toolbox and you're bound to find one common thing - a small black wheel, about 3" thick with a cardboard ring in the middle. Electrical tape has been around since 1946 and it's one of the most universally used types of tape, but what is it?

Electrical tape is typically made of vinyl or rubber material and comes in various colors, with black being the most common. The tape's adhesive side adheres firmly to itself when wrapped around wires, creating a secure and tight seal. This insulation helps to maintain the integrity of electrical circuits by guarding against exposure to moisture, dust, and other environmental factors.

Is Electrical Tape Waterproof?

Electrical tape is not waterproof and is known for operating in dry and hot situations most other types of tape could not withstand. Due to the fact that electrical tape is used in electrical connections, great consideration should be given to any situation where electrical tape is used near water. Even if not fully submerged, electrical wires and connections should be kept free from moisture-laden environments.

Can You Use Duct Tape Instead of Electrical Tape?

Electrical tape possesses two unique qualities that make it a better option than duct tape:

- Its flexibility: electrical tape can flex and stretch to fit tightly over electrical connections and adhere to itself to create a level of protection from the environment.

- The material: because electrical tape does not contain cloth or paper, it has a higher heat tolerance and can withstand temperatures in temporary residential and low-voltage applications.

Because duct tape is not flexible and flammable, it should never be used in an electrical application. The adhesive used in duct tape also leaves a large amount of residue and makes future work even more difficult. Do yourself a favor and grab a roll of high-quality electrical tape.

Pros of Using Electrical Tape

- Easy Access: Electrical tape is widely available in hardware stores, making it a convenient go-to solution for quick fixes, especially when traditional caps are not on hand. In emergencies, it can be a lifesaver.

- Insulation Benefits: The primary purpose of electrical tape is to insulate wires, protecting against electric shocks and minimizing the risk of short circuits. When applied correctly, it acts as a barrier between exposed wires, reducing potential hazards.

- Adaptability to Various Wire Shapes: Electrical tape's flexible nature allows it to conform to different wire shapes and sizes, making it versatile for various applications. Its adaptability ensures it can fit snugly around irregular wire configurations.

- Cost-Effectiveness: Compared to specialized connectors like wing nuts or twist-on caps, electrical tape is budget-friendly. This cost-effectiveness is appealing to DIY enthusiasts and those looking for affordable solutions.

Cons of Using Electrical Tape

- Limited Long-Term Reliability: While electrical tape works well for temporary fixes, it lacks the long-lasting reliability of traditional caps. Over time, the adhesive may weaken, compromising the connection's effectiveness.

- Vulnerable to Environmental Factors: Unlike caps designed for durability, electrical tape is more susceptible to damage from heat, moisture, and other environmental elements. This vulnerability may lead to premature failure of the connection.

- Potential Non-Compliance with Safety Standards: In professional electrical installations, it's essential to adhere to industry standards and safety regulations. Using electrical tape instead of approved caps might not meet these requirements, posing safety risks.

- Time-Consuming Application: Properly applying electrical tape to ensure a secure connection can be more time-consuming compared to using caps. Complex wiring setups may require more effort and precision.

When Can Electrical Tape Be Used?

- Temporary Repairs in Emergency Situations: In urgent scenarios where immediate repairs are necessary, and traditional caps are unavailable, electrical tape can serve as a temporary solution until proper repairs can be done.

- Low-Risk Applications with Minimal Safety Concerns: For low-voltage applications with minimal safety risks, using electrical tape temporarily may be acceptable. However, it's essential to monitor and replace it regularly.

- Wrapping Proper Connections: It is common practice to wrap wire nuts and the wire with electrical tape to minimize movement of the wires and the intrusion of moisture. Although not as common today, electrical tape was previously used to wrap electrical outlets during wiring.

Importance of Industry Standards and Safety Regulations

Adhering to professional guidelines and safety codes is critical in electrical installations. While electrical tape can provide temporary insulation, it does not guarantee the same level of safety as traditional caps approved by industry standards. Prioritizing safety over convenience is paramount.

Tips for Safely Using Electrical Tape

Using electrical tape safely is essential to ensure effective insulation and protection in electrical connections. Here are some helpful tips to follow:

- Select High-Quality Electrical Tape: Opt for good-quality electrical tape from reputable brands to ensure proper insulation and adhesive strength. Low-quality tape may not provide adequate protection and could lead to safety hazards.

- Clean and Dry Surfaces: Ensure that the surfaces to be taped are clean and dry before applying the tape. Removing dirt, dust, or moisture will help the tape adhere better and improve its effectiveness.

- Stretch the Tape Slightly: When applying the tape, stretch it slightly as you wrap it around the wires. This stretching helps the adhesive bond more securely and provides a tighter seal.

- Overlap the Tape Layers: For improved insulation, overlap the tape layers by at least half of its width. This ensures a more robust barrier against electrical currents and environmental factors.

- Use the Right Amount of Tape: Avoid using too little or too much tape. Using an appropriate amount will provide the necessary insulation without creating bulk that could interfere with fittings or connections.

- Properly Seal the Ends: Always seal the ends of the electrical tape securely to prevent it from unraveling. This will maintain the tape's effectiveness and prevent potential hazards.

- Be Mindful of Heat: If you are working on connections that generate heat, ensure the electrical tape used is rated for high-temperature applications. Regular electrical tape may melt or degrade under such conditions.

- Monitor and Replace as Needed: Periodically check taped connections for signs of wear, damage, or adhesive deterioration. Replace any tape that shows signs of wear to maintain a secure and safe electrical connection.

By following these safety tips, you can effectively use electrical tape for temporary repairs and insulating electrical connections, keeping your electrical systems secure and protected. Always prioritize safety and adhere to industry standards in all your electrical installations.

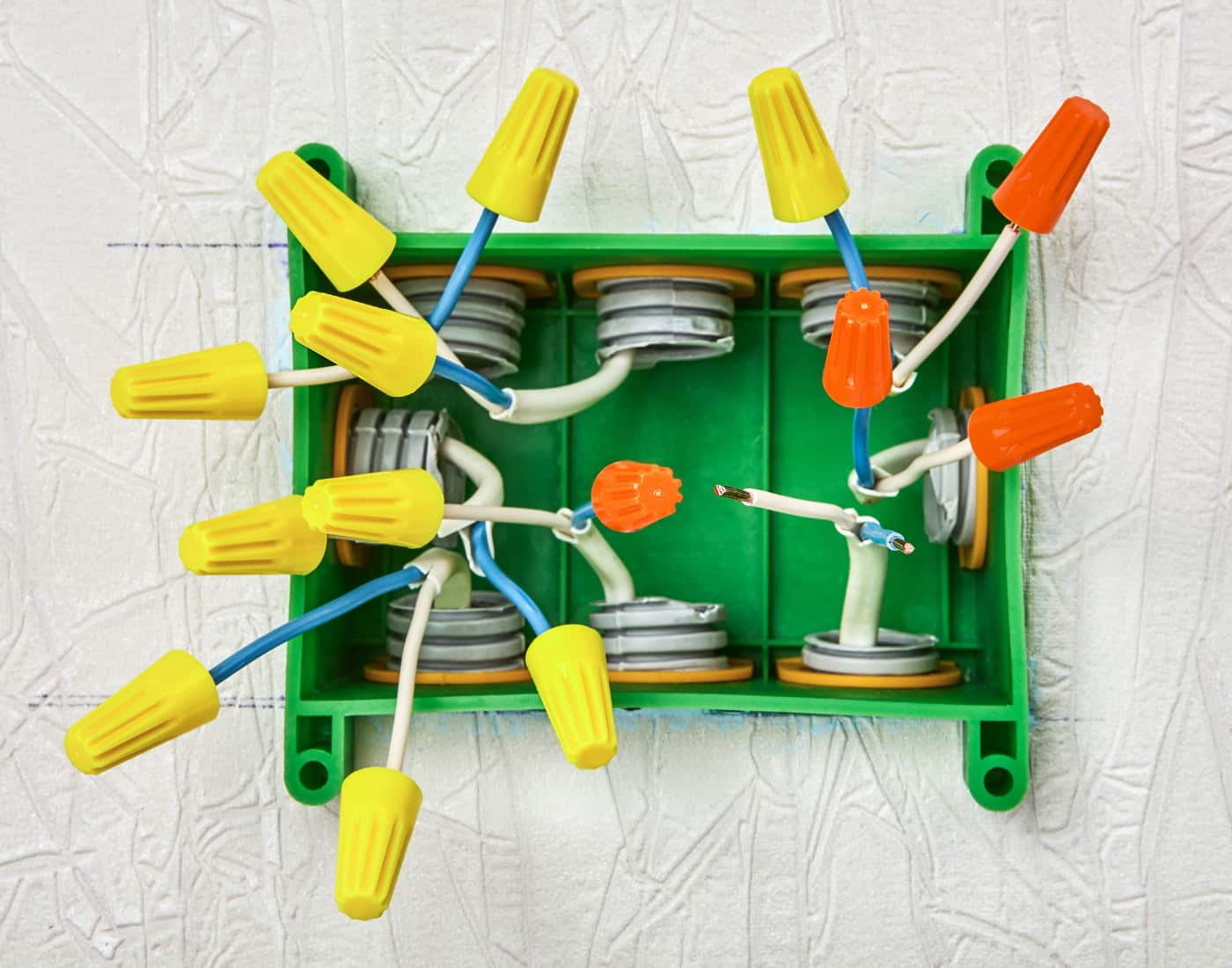

What is a Wire Nut?

A wire nut, also known as a wire caps, wire connector, or twist-on connector, is a small but essential component used in electrical installations to securely connect and insulate copper wire and aluminum wiring. It consists of a cone-shaped plastic body with a threaded interior and a cap that screws onto the body.

Wire nuts come in various sizes and colors to accommodate different wire gauges and configurations. When connecting wires, electricians or DIY enthusiasts twist the exposed ends of the wires together and insert them into the wire nut's open end. As the cap is tightened onto the body, the wire nut firmly secures the twisted wires, creating a reliable electrical connection.

The plastic body also provides insulation, protecting against electrical shocks and environmental factors. Wire nuts are widely used for both residential and commercial electrical applications and are considered a standard and safe method for joining wires.

Types of Wire Nuts

There are several types of wire nuts available, each designed to accommodate specific wire sizes and configurations. Commonly used types include:

- Standard Wire Nuts: These are the most widely used wire nuts and come in various colors to indicate their size and capacity. They can typically handle a range of wire gauges and are suitable for general-purpose electrical connections.

- Winged Wire Nuts: These wire nuts have extended wings or fins that provide extra leverage for twisting and tightening. They are particularly useful when working with larger wire combinations or in situations where a more secure grip is required.

- High-Temperature Wire Nuts: These specialized wire nuts are designed to withstand higher temperatures, making them ideal for connections near heat sources or in applications with elevated temperatures.

- Waterproof Wire Nuts: As the name suggests, waterproof wire nuts are designed to provide a watertight seal. They are commonly used in outdoor electrical installations or areas where moisture is a concern.

- Push-in Wire Connectors: Unlike standard twist-on wire nuts, push-in wire connectors feature a spring-loaded mechanism that allows wires to be inserted directly into the connector. These connectors offer quick and easy installation without the need for twisting, making them popular for time-sensitive projects.

- Underground Wire Nuts: These wire nuts are specifically designed to be buried underground and protect connections from moisture and soil contaminants, making them suitable for landscape lighting and irrigation systems.

- Multi-port Wire Connectors: Multi-port wire connectors have multiple openings, allowing several wires to be connected together at once. They are handy in situations where multiple connections need to be made, reducing the need for separate connectors.

Each type of wire nut serves a specific purpose, and it's crucial to choose the appropriate one based on the wire size, application, and environmental factors to ensure a secure and reliable electrical connection.

The Role of Caps in Long-Term Reliability

While electrical tape can be a useful temporary solution to cover bare wires, it should not replace traditional caps for permanent electrical connections or splicing wires. Wire nuts are designed for long-lasting connections, providing better protection against environmental factors and ensuring connection integrity over time.

The longevity and safety offered by approved wire nuts are essential for reliable electrical installations. Always prioritize safety, adhere to industry standards, and consider seeking professional help for complex electrical work. Remember, electrical safety is never something to compromise.

Knowing When to Seek Professional Assistance

Recognize when complex wiring projects or high-voltage situations require expert electrical help. Avoid DIY attempts in these cases to prevent safety hazards. Safety should always be the top priority. When it comes to live wires and electrical installations, it's best to leave it to the experts. Licensed electricians possess the knowledge, skills, and experience to handle electrical systems safely and efficiently. Don't risk compromising your safety or the integrity of your electrical circuits with temporary fixes. Whether you need repairs, installations, or upgrades, contact a top-rated licensed electrician from MSS Ortiz by calling (919) 382-0832 or filling out our contact form. Your peace of mind is just a call away – prioritize safety and entrust your electrical needs to the professionals.